THE TEAM

GLOBAL LEADERSHIP

Eugene Els

AFX HOLDINGS

AFROMIX

Eugene Els is a mechanical engineer with numerous years of experience in the manufacturing and mining industry. Most of his experience is rooted in the field of agitation, supporting manufacturing processes. He possesses extensive process and mechanical design knowledge, and has specialised experience with agitator design.

Eugene was one of the founding members of AFROMIX in 2006 and held the position of Technical Director. In 2010, he became the Managing Director of AFROMIX. The company has since progressed, establishing itself as a market leader on the African Continent. Eugene has a clear vision of customer service and adopts a zero compromise on quality. Eugene has been instrumental in the development of AFX’s specialised mechanical design software, its own fabrication facility, as well as other industry firsts which include the development and design of the AFX range of peristaltic pumps.

In 2012, when AFX Holdings acquired AFROMIX, Eugene became the group Managing Director. The group has expanded even further under his guidance with the successful opening of North American and European divisions under the AFX Holdings Company.

JJ Strydom

Projects Director

AFROMIX Africa

JJ embarked upon his professional career as a Design Engineer at B&E International. He designed and co-designed numerous mobile screening plants consisting of a track-driven loading hopper unit and non-driven triple screen unit. In 1995, he was appointed as the Project Engineer and was tasked with the responsibility of the manufacturing of 1000 ton/hr mobile screening plants. JJ was later promoted to Section Engineer in 1996 where he managed three operations in Namibia. He returned to Johannesburg in 2002 where he headed up and managed the Oil Analysis and Service Program at B&E International.

JJ’s exceptional engineering knowledge and task execution capabilities did not go unnoticed. He moved to AFROMIX in 2007, assuming the role of Project Manager. He ensured that AFROMIX’s products were held to the highest standards and assisted in forging the growth of AFROMIX’s reputation throughout the market. Possessing an extensive knowledge in the engineering field and, more particularly, in pumping and mixing, he became the Projects Director in 2010 at AFROMIX. JJ has developed a vast knowledge of the African market which is complimented by regular site visits. This granted him the ability to not only understand the issues faced on-site with most applications, but it has also given him the ability to solve the problems on-site, as well as ensure that the correct measures are implemented back in-house to ensure that our products work for all types of sites.

Toby Frostwick

Toby Frostwick

AFX Mixing and Pumping Technologies LTD – Europe

Toby Frostwick is a seasoned mechanical engineer with over four decades of experience in the fluid handling and processing industries. His career includes senior roles such as Global Product Manager at Weir Group Plc and Engineered Products Manager at Watson-Marlow Pump Group, where he led global strategies and delivered innovative, high-performance solutions across multiple sectors.

Originally trained in mechanical and production engineering, Toby developed a specialised focus in peristaltic pump technology. He is widely regarded as one of the world’s leading authorities on peristaltic hose pumps, known for his technical expertise, precision, and practical problem-solving skills. His ability to optimise systems has delivered significant operational and capital cost savings for clients worldwide.

Toby has worked alongside AFROMIX since 2008, initially contributing to the development and growth of the company’s pump division. His input was instrumental in expanding the AFX pump range capabilities and building its reputation for reliability and performance. In 2015, he assumed leadership of AFX’s European operations, where he has since driven growth in both pumping and mixing solutions across industries including mining, water treatment, chemical processing, and food and beverage.

Today, Toby remains a key member of the AFX global leadership team, serving as a trusted advisor, mentor, and subject matter expert both within the organisation and across the international engineering community.

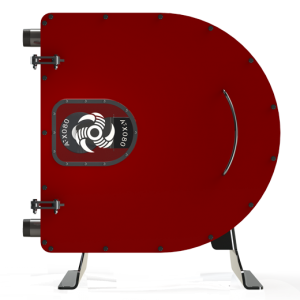

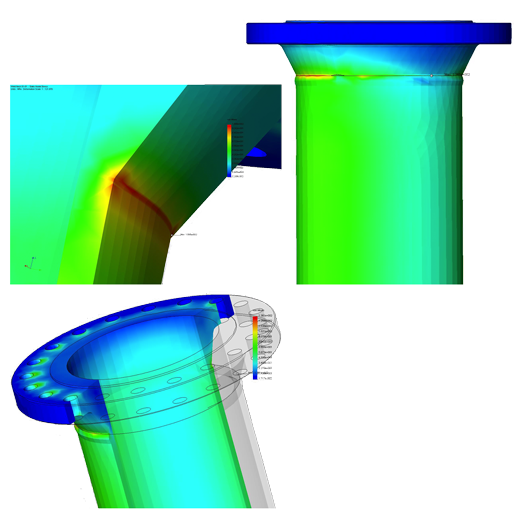

At the heart of every AFX peristaltic pump lies a heavy-duty peristaltic hose specially developed to work hand in hand with the pump roller technology installed in the AFX PUMP SERIES. We stock a comprehensive range of hose materials for each pump to be compatible with the unique chemical and abrasive characteristics of every application. A carefully designed and manufactured hose element is the single most vital component for the performance durability and efficiency of any peristaltic pump. To ensure a good pump you must have a good hose, and this is where AFX excels. Each hose we supply is built under stringent quality control measures, using high-quality, compounded rubbers, reinforced with four individual layers of braided nylon carefully set at optimum angles. Once cured, the outer diameter of each hose is precision machined to exacting tolerances ensuring a perfectly sized hose. An accurately sized hose ensures perfect compression, which eliminates internal slip (which reduces pump efficiency and allows for the abrasive slurries to prematurely destroy the hose).

At the heart of every AFX peristaltic pump lies a heavy-duty peristaltic hose specially developed to work hand in hand with the pump roller technology installed in the AFX PUMP SERIES. We stock a comprehensive range of hose materials for each pump to be compatible with the unique chemical and abrasive characteristics of every application. A carefully designed and manufactured hose element is the single most vital component for the performance durability and efficiency of any peristaltic pump. To ensure a good pump you must have a good hose, and this is where AFX excels. Each hose we supply is built under stringent quality control measures, using high-quality, compounded rubbers, reinforced with four individual layers of braided nylon carefully set at optimum angles. Once cured, the outer diameter of each hose is precision machined to exacting tolerances ensuring a perfectly sized hose. An accurately sized hose ensures perfect compression, which eliminates internal slip (which reduces pump efficiency and allows for the abrasive slurries to prematurely destroy the hose).

Peristaltic pumps are by nature inherently pulsing in operation. Excessive pressure spikes and pulsations within the pump system can be extremely damaging to the pump hose and the process system.

Peristaltic pumps are by nature inherently pulsing in operation. Excessive pressure spikes and pulsations within the pump system can be extremely damaging to the pump hose and the process system. The primary reason for hose failure is from cyclic fatigue (number of hose compressions). Pump hose failure is inevitable, but exactly when hose failure will occur is dependent upon many factors and may not always be at a convenient time when a technician is watching the pump.

The primary reason for hose failure is from cyclic fatigue (number of hose compressions). Pump hose failure is inevitable, but exactly when hose failure will occur is dependent upon many factors and may not always be at a convenient time when a technician is watching the pump. Our extensive range of peristaltic hose pumps includes one of the largest pumps of this type in the world. Our 150mm pump has a maximum flow rate of 147m³/hr and can deliver pressures up to 10 Bar. These units are ideal for thickener underflow applications.

Our extensive range of peristaltic hose pumps includes one of the largest pumps of this type in the world. Our 150mm pump has a maximum flow rate of 147m³/hr and can deliver pressures up to 10 Bar. These units are ideal for thickener underflow applications. OPERATING PRINCIPLE

OPERATING PRINCIPLE PUMP SELECTION

PUMP SELECTION spreading from mining processes to chemical and agricultural testing laboratories as well as personal care and pharmaceutical laboratories, the need for this equipment is on the rise. Pilot plants and bench plants are small modular industrial systems, which are designed and implemented to generate information and understand particular behaviours during test or trial periods. This is usually done before building the large full-scale plant, which entails large capital outlays as well as major risks associated with the process. The use of the pilot or bench plants enables one to make a calculated and informed decision on whether or not to move forward with the full-scale operation. It equips the client with freedom to run tests accurately as well as change and modify procedures on the smaller scale.

spreading from mining processes to chemical and agricultural testing laboratories as well as personal care and pharmaceutical laboratories, the need for this equipment is on the rise. Pilot plants and bench plants are small modular industrial systems, which are designed and implemented to generate information and understand particular behaviours during test or trial periods. This is usually done before building the large full-scale plant, which entails large capital outlays as well as major risks associated with the process. The use of the pilot or bench plants enables one to make a calculated and informed decision on whether or not to move forward with the full-scale operation. It equips the client with freedom to run tests accurately as well as change and modify procedures on the smaller scale.

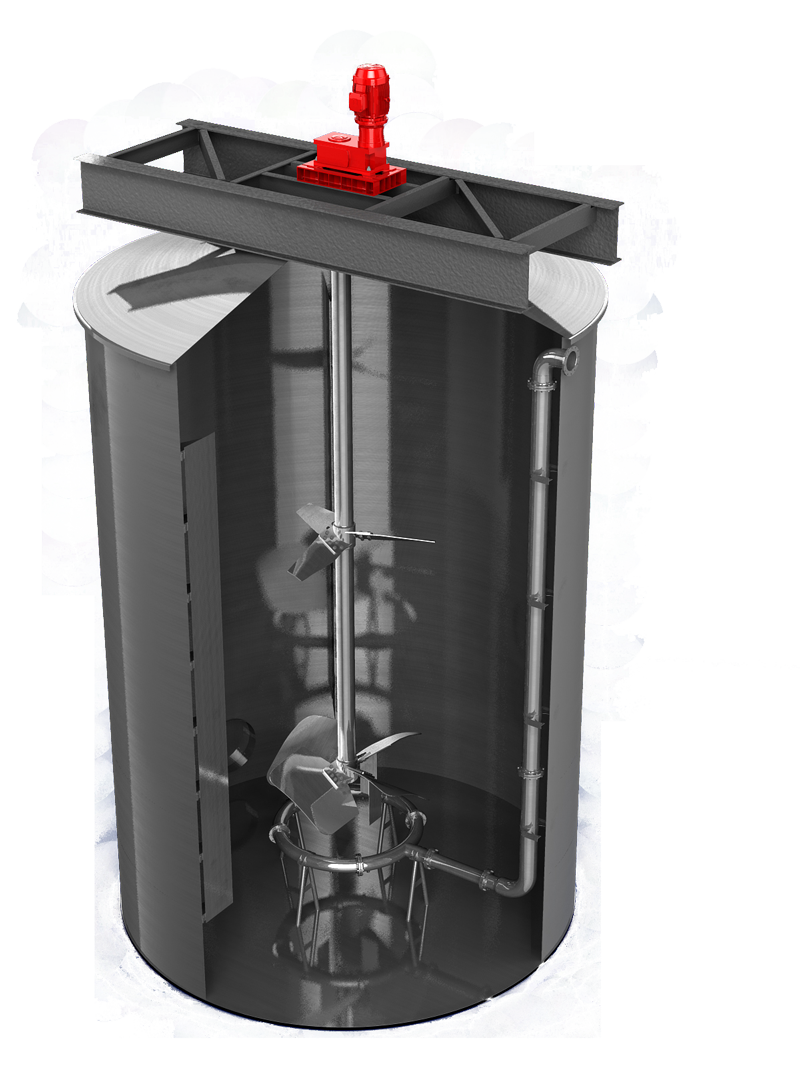

BAFFLES AND BAFFLE COILS

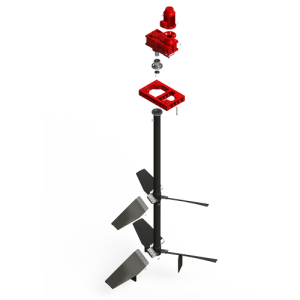

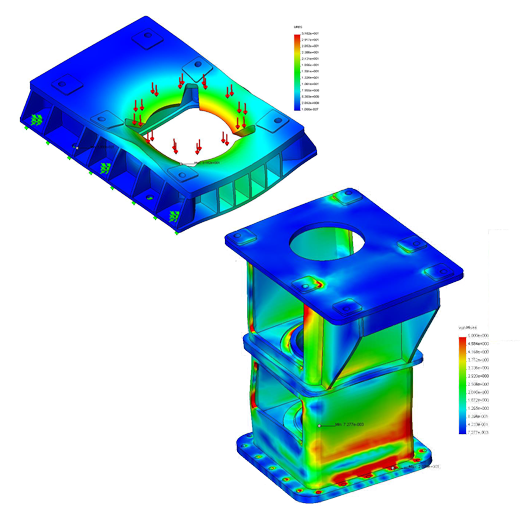

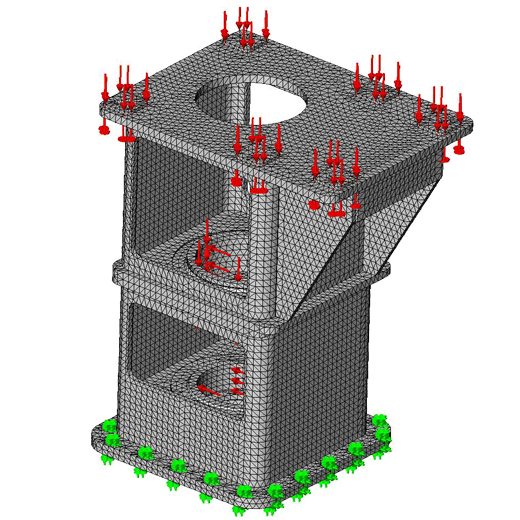

BAFFLES AND BAFFLE COILS Mounting bases and pedestals are critical in ensuring that the gearbox of the agitator is correctly aligned and mounted to the supporting beam structure. Our pedestals and bases are designed to significantly reduce the potential of twisting or flexing within the gearbox housing; which is often a common cause of some gearbox failures.

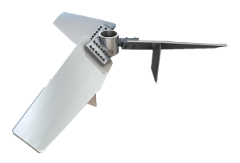

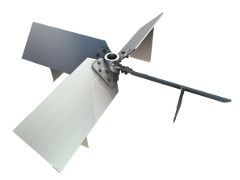

Mounting bases and pedestals are critical in ensuring that the gearbox of the agitator is correctly aligned and mounted to the supporting beam structure. Our pedestals and bases are designed to significantly reduce the potential of twisting or flexing within the gearbox housing; which is often a common cause of some gearbox failures. IMPELLER TYPE: F3

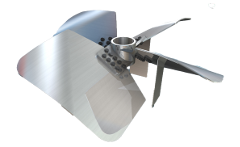

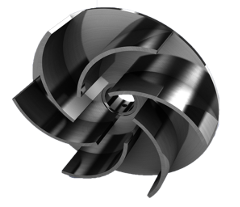

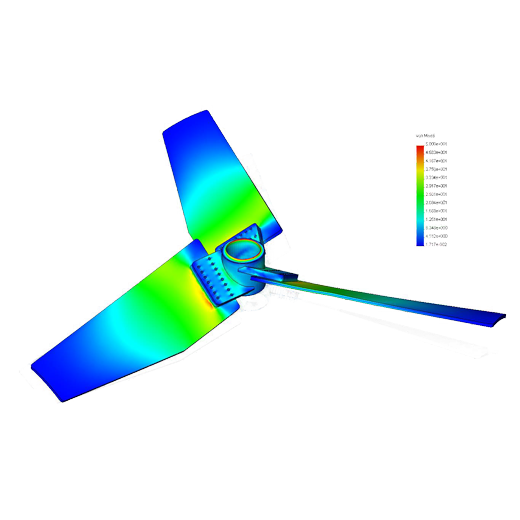

IMPELLER TYPE: F3 IMPELLER TYPE: FS4

IMPELLER TYPE: FS4 IMPELLER TYPE: P3

IMPELLER TYPE: P3 IMPELLER TYPE: P4

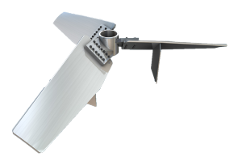

IMPELLER TYPE: P4 FOLDING IMPELLERS

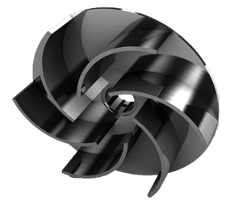

FOLDING IMPELLERS IMPELLER TYPE: R6

IMPELLER TYPE: R6 FCE3 CLEAN EDGE IMPELLER

FCE3 CLEAN EDGE IMPELLER

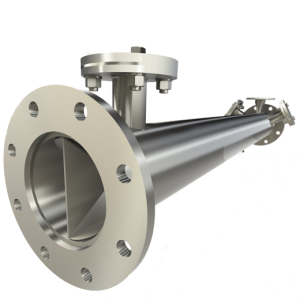

PRESSURE OXIDATION

PRESSURE OXIDATION GAS DISPERSION

GAS DISPERSION IRON REMOVAL

IRON REMOVAL CYANIDE DETOX

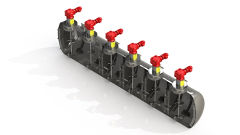

CYANIDE DETOX PEDESTAL MOUNTED MIXERS

PEDESTAL MOUNTED MIXERS R6 PUMP IMPELLER

R6 PUMP IMPELLER

SIDE ENTRY AGITATORS

SIDE ENTRY AGITATORS TOP ENTRY MIXERS

TOP ENTRY MIXERS

SMALL TOP ENTRY AGITATORS

SMALL TOP ENTRY AGITATORS