WOMEN AT WORK

Why Women Matter in the Workforce – and What It Means for AFX

In honour of Women’s Month | 7 August 2025 | By Anje Barkhuizen

There’s no denying that businesses do better when they reflect the real world. And the real world is made up of women with strength, skill, and a point of view that matters.

Inside AFX

At AFX, women operate globally across various departments like engineering, supply chain, finance, marketing, HR, and operations. Their presence translates directly into better teamwork, clearer communication, stronger client relationships, and smarter solutions.

By embracing and supporting women in technical and non-technical roles, we foster an environment where diverse thinking strengthens outcomes. That doesn’t diminish any colleague but rather, elevates the whole team. Our teams are richer with insight, creativity, and resilience when we bring different perspectives together.

Our Commitment at AFX

We are working toward more than just meeting targets. We are building a company where:

• Women can lead with confidence, skill, and clarity.

• Careers are shaped through mentorship, inclusive policies, and flexible support.

• Every team member (regardless of gender) can grow, contribute, and win together.

Women at AFX are showing what’s possible when talent is supported. We’re proud to back them, learn from them, and grow with them.

Because here’s the truth: supporting women doesn’t mean someone else loses out. It means the whole system gets stronger.

AFX Moves Forward

At AFX, we believe in people. When we invest in our female colleagues, we invest in better ideas, better outcomes, and a future we can all be proud of.

This Women’s Month, and every month, we recognise the power of women at work. And we remain committed to building a space where their impact isn’t just seen but celebrated.

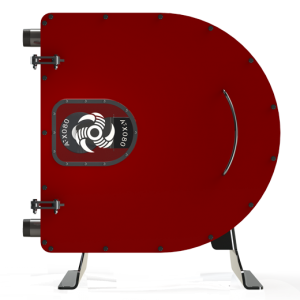

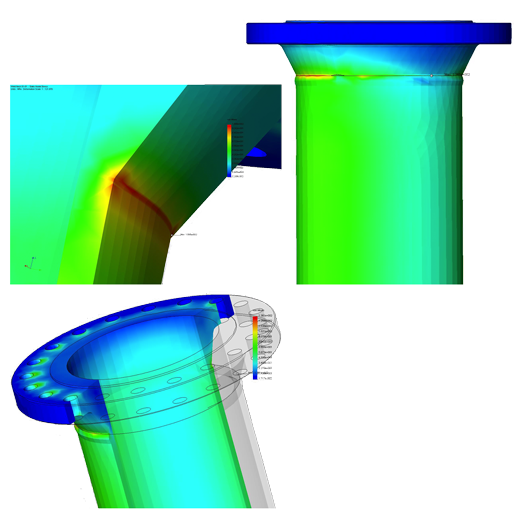

At the heart of every AFX peristaltic pump lies a heavy-duty peristaltic hose specially developed to work hand in hand with the pump roller technology installed in the AFX PUMP SERIES. We stock a comprehensive range of hose materials for each pump to be compatible with the unique chemical and abrasive characteristics of every application. A carefully designed and manufactured hose element is the single most vital component for the performance durability and efficiency of any peristaltic pump. To ensure a good pump you must have a good hose, and this is where AFX excels. Each hose we supply is built under stringent quality control measures, using high-quality, compounded rubbers, reinforced with four individual layers of braided nylon carefully set at optimum angles. Once cured, the outer diameter of each hose is precision machined to exacting tolerances ensuring a perfectly sized hose. An accurately sized hose ensures perfect compression, which eliminates internal slip (which reduces pump efficiency and allows for the abrasive slurries to prematurely destroy the hose).

At the heart of every AFX peristaltic pump lies a heavy-duty peristaltic hose specially developed to work hand in hand with the pump roller technology installed in the AFX PUMP SERIES. We stock a comprehensive range of hose materials for each pump to be compatible with the unique chemical and abrasive characteristics of every application. A carefully designed and manufactured hose element is the single most vital component for the performance durability and efficiency of any peristaltic pump. To ensure a good pump you must have a good hose, and this is where AFX excels. Each hose we supply is built under stringent quality control measures, using high-quality, compounded rubbers, reinforced with four individual layers of braided nylon carefully set at optimum angles. Once cured, the outer diameter of each hose is precision machined to exacting tolerances ensuring a perfectly sized hose. An accurately sized hose ensures perfect compression, which eliminates internal slip (which reduces pump efficiency and allows for the abrasive slurries to prematurely destroy the hose).

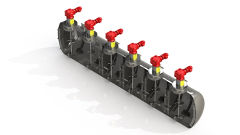

Peristaltic pumps are by nature inherently pulsing in operation. Excessive pressure spikes and pulsations within the pump system can be extremely damaging to the pump hose and the process system.

Peristaltic pumps are by nature inherently pulsing in operation. Excessive pressure spikes and pulsations within the pump system can be extremely damaging to the pump hose and the process system. The primary reason for hose failure is from cyclic fatigue (number of hose compressions). Pump hose failure is inevitable, but exactly when hose failure will occur is dependent upon many factors and may not always be at a convenient time when a technician is watching the pump.

The primary reason for hose failure is from cyclic fatigue (number of hose compressions). Pump hose failure is inevitable, but exactly when hose failure will occur is dependent upon many factors and may not always be at a convenient time when a technician is watching the pump. Our extensive range of peristaltic hose pumps includes one of the largest pumps of this type in the world. Our 150mm pump has a maximum flow rate of 147m³/hr and can deliver pressures up to 10 Bar. These units are ideal for thickener underflow applications.

Our extensive range of peristaltic hose pumps includes one of the largest pumps of this type in the world. Our 150mm pump has a maximum flow rate of 147m³/hr and can deliver pressures up to 10 Bar. These units are ideal for thickener underflow applications. OPERATING PRINCIPLE

OPERATING PRINCIPLE PUMP SELECTION

PUMP SELECTION spreading from mining processes to chemical and agricultural testing laboratories as well as personal care and pharmaceutical laboratories, the need for this equipment is on the rise. Pilot plants and bench plants are small modular industrial systems, which are designed and implemented to generate information and understand particular behaviours during test or trial periods. This is usually done before building the large full-scale plant, which entails large capital outlays as well as major risks associated with the process. The use of the pilot or bench plants enables one to make a calculated and informed decision on whether or not to move forward with the full-scale operation. It equips the client with freedom to run tests accurately as well as change and modify procedures on the smaller scale.

spreading from mining processes to chemical and agricultural testing laboratories as well as personal care and pharmaceutical laboratories, the need for this equipment is on the rise. Pilot plants and bench plants are small modular industrial systems, which are designed and implemented to generate information and understand particular behaviours during test or trial periods. This is usually done before building the large full-scale plant, which entails large capital outlays as well as major risks associated with the process. The use of the pilot or bench plants enables one to make a calculated and informed decision on whether or not to move forward with the full-scale operation. It equips the client with freedom to run tests accurately as well as change and modify procedures on the smaller scale.

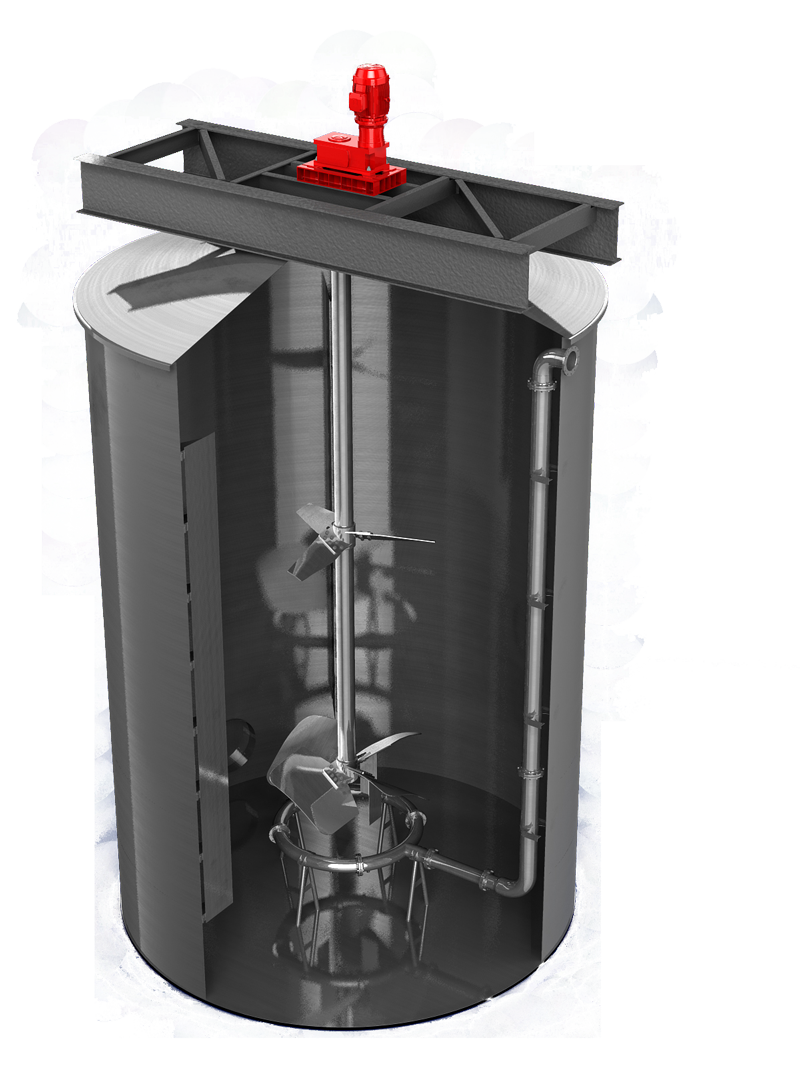

BAFFLES AND BAFFLE COILS

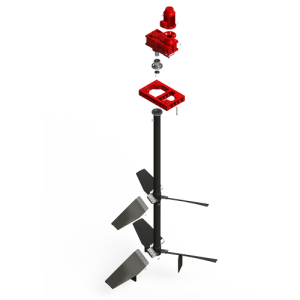

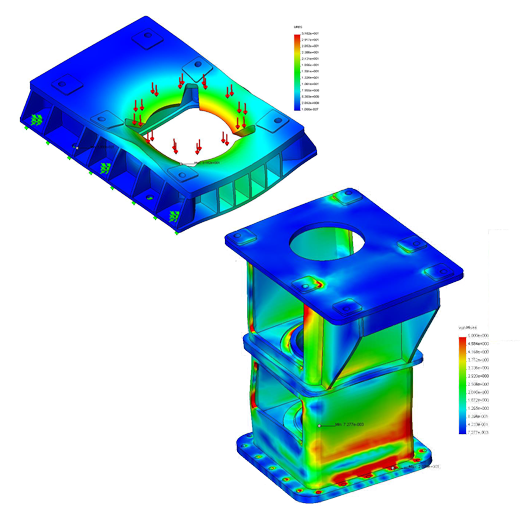

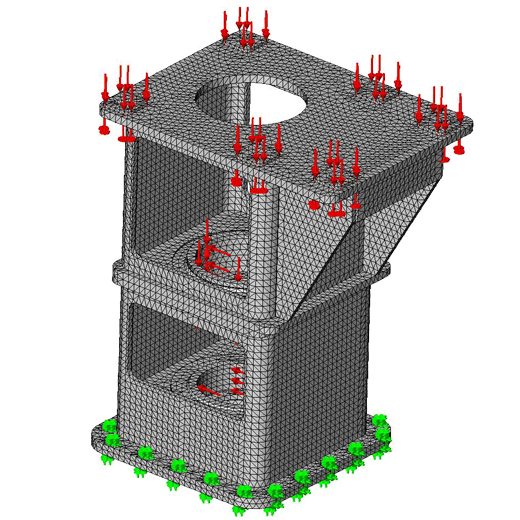

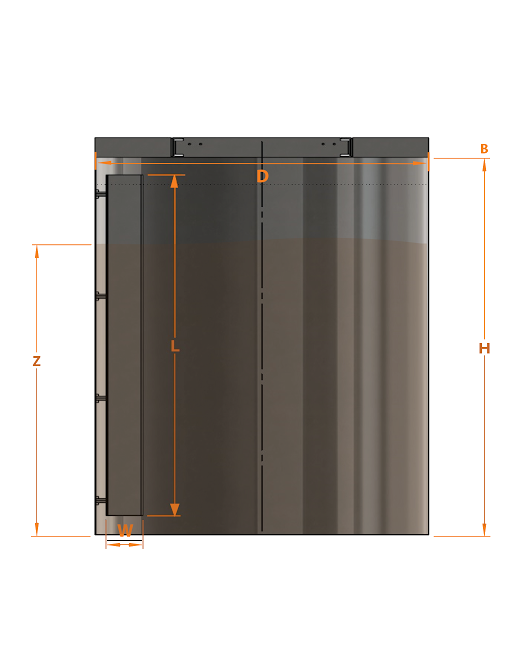

BAFFLES AND BAFFLE COILS Mounting bases and pedestals are critical in ensuring that the gearbox of the agitator is correctly aligned and mounted to the supporting beam structure. Our pedestals and bases are designed to significantly reduce the potential of twisting or flexing within the gearbox housing; which is often a common cause of some gearbox failures.

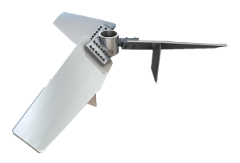

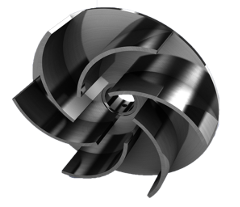

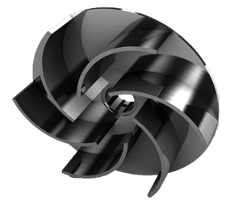

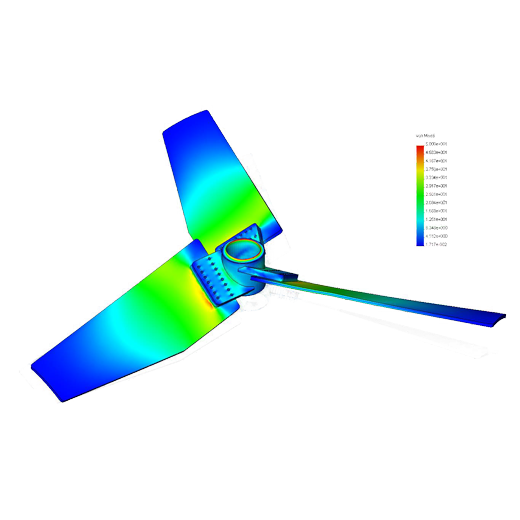

Mounting bases and pedestals are critical in ensuring that the gearbox of the agitator is correctly aligned and mounted to the supporting beam structure. Our pedestals and bases are designed to significantly reduce the potential of twisting or flexing within the gearbox housing; which is often a common cause of some gearbox failures. IMPELLER TYPE: F3

IMPELLER TYPE: F3 IMPELLER TYPE: FS4

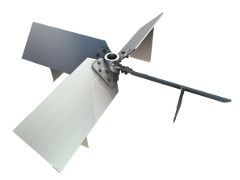

IMPELLER TYPE: FS4 IMPELLER TYPE: P3

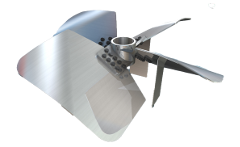

IMPELLER TYPE: P3 IMPELLER TYPE: P4

IMPELLER TYPE: P4 FOLDING IMPELLERS

FOLDING IMPELLERS IMPELLER TYPE: R6

IMPELLER TYPE: R6 FCE3 CLEAN EDGE IMPELLER

FCE3 CLEAN EDGE IMPELLER

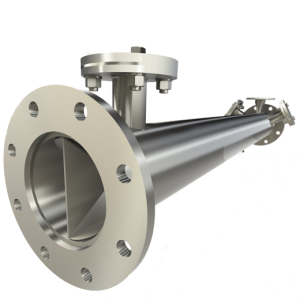

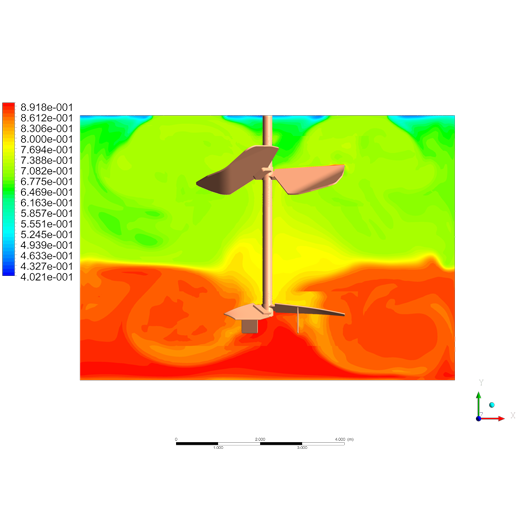

PRESSURE OXIDATION

PRESSURE OXIDATION GAS DISPERSION

GAS DISPERSION IRON REMOVAL

IRON REMOVAL CYANIDE DETOX

CYANIDE DETOX PEDESTAL MOUNTED MIXERS

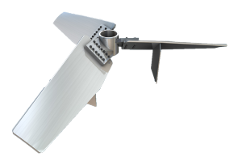

PEDESTAL MOUNTED MIXERS R6 PUMP IMPELLER

R6 PUMP IMPELLER

SIDE ENTRY AGITATORS

SIDE ENTRY AGITATORS TOP ENTRY MIXERS

TOP ENTRY MIXERS

SMALL TOP ENTRY AGITATORS

SMALL TOP ENTRY AGITATORS

Recent Comments