AFX

HOSES

At the heart of every AFX peristaltic pump lies a heavy-duty peristaltic hose specially developed to work hand in hand with the pump roller technology installed in the AFX PUMP SERIES. We stock a comprehensive range of hose materials for each pump to be compatible with the unique chemical and abrasive characteristics of every application. A carefully designed and manufactured hose element is the single most vital component for the performance durability and efficiency of any peristaltic pump. To ensure a good pump you must have a good hose, and this is where AFX excels. Each hose we supply is built under stringent quality control measures, using high-quality, compounded rubbers, reinforced with four individual layers of braided nylon carefully set at optimum angles. Once cured, the outer diameter of each hose is precision machined to exacting tolerances ensuring a perfectly sized hose. An accurately sized hose ensures perfect compression, which eliminates internal slip (which reduces pump efficiency and allows for the abrasive slurries to prematurely destroy the hose).

DESIGNED AND MANUFACTURED TO PERFECTION

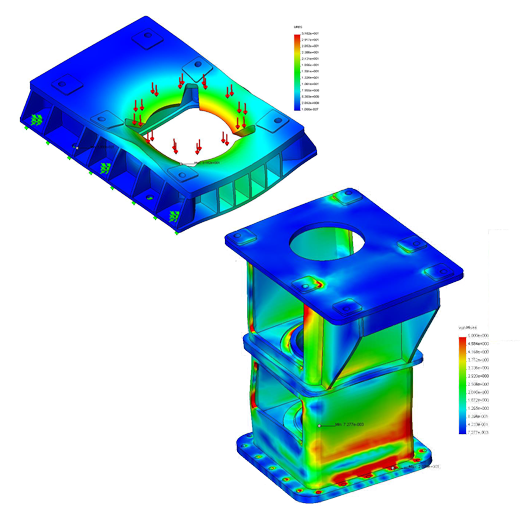

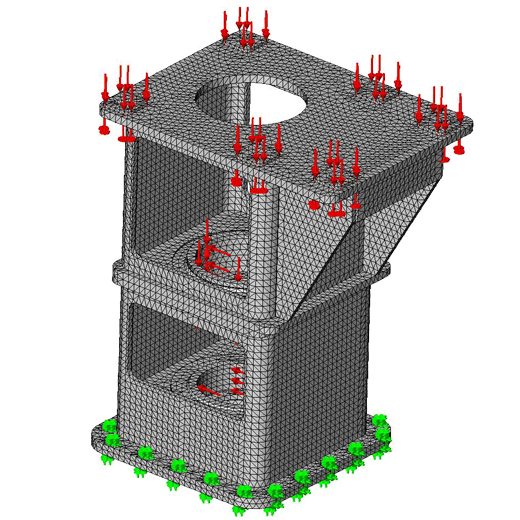

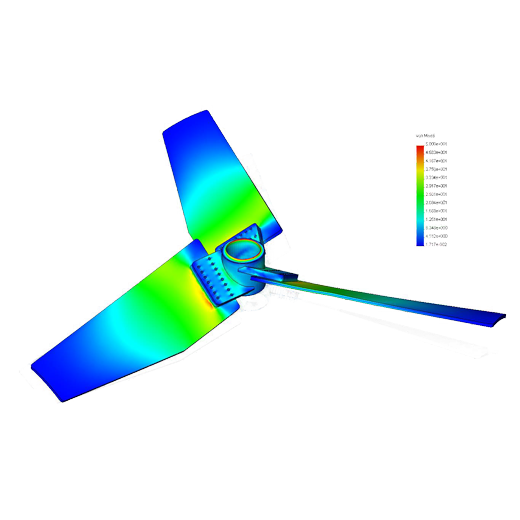

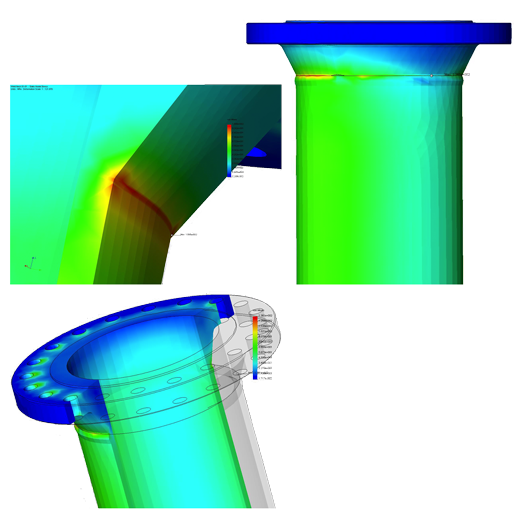

Utilising design tools such as Finite Element Analysis (FEA), backed up by physical tests and theoretical calculations, our hoses are designed to perfection – right down to the position of the reinforcing layers, the braid angles, cord thickness, and the thickness of the surrounding rubber. The roller geometry and the profile of the pump housing are all designed and engineered to optimise the performance of the pump hose. To ensure a good repeatable and consistent hose life, you must have a hose built and machined to exacting tolerances. To us, the ISO standards are not good enough. All our hoses exceed the requirements set out in ISO 1307 and DIN7715.

AVAILABLE HOSE LINER MATERIALS

NATURAL RUBBER (NR) |

EPDM |

| A general purpose material with excellent mechanical and abrasion resistant properties. Suitable for all water-based applications and mild acids, alkalis or oxidising agents. Max. fluid temperature: 80 °C Min. temperature: -20 °C | Ethylene propylene diene rubber. Excellent chemical resistance, especially to ketones, esters, alcohols and concentrated acids. Max. fluid temperature: 90 °C Min. temperature: -10 °C |

NITRILE (NBR) |

CSM (HYPALON®) |

| Acrylonitrile butadiene rubber. A durable material resistant to oils, greases, alkalis and detergents. Compliant to European BfR standards, this liner can also be used in a wide range of applications in the food industry. Max. fluid temperature: 80 °C Min. temperature: -10 °C | Chlorosuphonyl polyethylene rubber. Excellent chemical resistance to high concentration acids, ozones, and other oxidising materials. Max. fluid temperature: 80 °C Min. temperature: -10 °C |

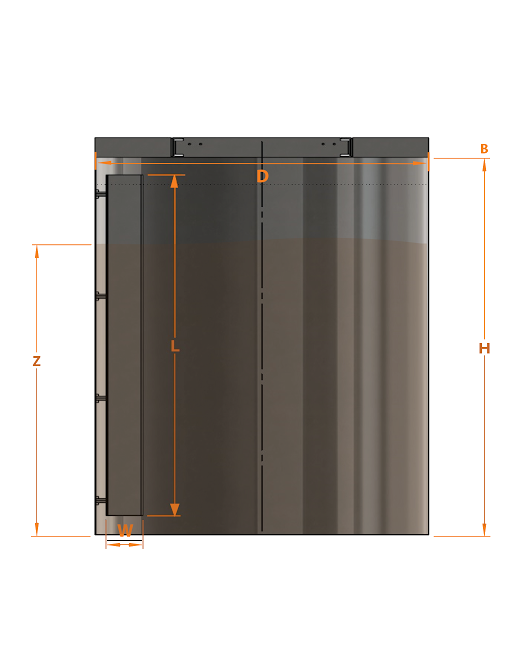

THE ANATOMY OF OUR HOSE

- Unground outer cover

- Precision ground finished hose

- Layers of reinforcement braid

- Inner hose liner

HOSES FOR USE IN OTHER MANUFACTURERS’ PUMPS

So confident are we about the quality of our hose, that we will supply hoses produced to original tolerances for many of the major peristaltic pump manufacturers pumps. We have successfully reduced operational costs for a large number of customers by using our hose in their existing peristaltic hose pumps.

CHEMICAL COMPATIBILITY CHART |

|

Chemical Compatibility Chart – 2016 |

Download |

At the heart of every AFX peristaltic pump lies a heavy-duty peristaltic hose specially developed to work hand in hand with the pump roller technology installed in the AFX PUMP SERIES. We stock a comprehensive range of hose materials for each pump to be compatible with the unique chemical and abrasive characteristics of every application. A carefully designed and manufactured hose element is the single most vital component for the performance durability and efficiency of any peristaltic pump. To ensure a good pump you must have a good hose, and this is where AFX excels. Each hose we supply is built under stringent quality control measures, using high-quality, compounded rubbers, reinforced with four individual layers of braided nylon carefully set at optimum angles. Once cured, the outer diameter of each hose is precision machined to exacting tolerances ensuring a perfectly sized hose. An accurately sized hose ensures perfect compression, which eliminates internal slip (which reduces pump efficiency and allows for the abrasive slurries to prematurely destroy the hose).

At the heart of every AFX peristaltic pump lies a heavy-duty peristaltic hose specially developed to work hand in hand with the pump roller technology installed in the AFX PUMP SERIES. We stock a comprehensive range of hose materials for each pump to be compatible with the unique chemical and abrasive characteristics of every application. A carefully designed and manufactured hose element is the single most vital component for the performance durability and efficiency of any peristaltic pump. To ensure a good pump you must have a good hose, and this is where AFX excels. Each hose we supply is built under stringent quality control measures, using high-quality, compounded rubbers, reinforced with four individual layers of braided nylon carefully set at optimum angles. Once cured, the outer diameter of each hose is precision machined to exacting tolerances ensuring a perfectly sized hose. An accurately sized hose ensures perfect compression, which eliminates internal slip (which reduces pump efficiency and allows for the abrasive slurries to prematurely destroy the hose).

Peristaltic pumps are by nature inherently pulsing in operation. Excessive pressure spikes and pulsations within the pump system can be extremely damaging to the pump hose and the process system.

Peristaltic pumps are by nature inherently pulsing in operation. Excessive pressure spikes and pulsations within the pump system can be extremely damaging to the pump hose and the process system. The primary reason for hose failure is from cyclic fatigue (number of hose compressions). Pump hose failure is inevitable, but exactly when hose failure will occur is dependent upon many factors and may not always be at a convenient time when a technician is watching the pump.

The primary reason for hose failure is from cyclic fatigue (number of hose compressions). Pump hose failure is inevitable, but exactly when hose failure will occur is dependent upon many factors and may not always be at a convenient time when a technician is watching the pump. Our extensive range of peristaltic hose pumps includes one of the largest pumps of this type in the world. Our 150mm pump has a maximum flow rate of 147m³/hr and can deliver pressures up to 10 Bar. These units are ideal for thickener underflow applications.

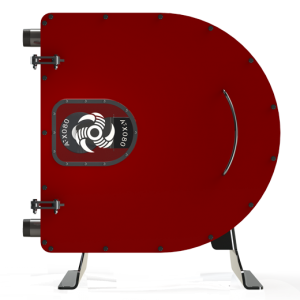

Our extensive range of peristaltic hose pumps includes one of the largest pumps of this type in the world. Our 150mm pump has a maximum flow rate of 147m³/hr and can deliver pressures up to 10 Bar. These units are ideal for thickener underflow applications. OPERATING PRINCIPLE

OPERATING PRINCIPLE PUMP SELECTION

PUMP SELECTION spreading from mining processes to chemical and agricultural testing laboratories as well as personal care and pharmaceutical laboratories, the need for this equipment is on the rise. Pilot plants and bench plants are small modular industrial systems, which are designed and implemented to generate information and understand particular behaviours during test or trial periods. This is usually done before building the large full-scale plant, which entails large capital outlays as well as major risks associated with the process. The use of the pilot or bench plants enables one to make a calculated and informed decision on whether or not to move forward with the full-scale operation. It equips the client with freedom to run tests accurately as well as change and modify procedures on the smaller scale.

spreading from mining processes to chemical and agricultural testing laboratories as well as personal care and pharmaceutical laboratories, the need for this equipment is on the rise. Pilot plants and bench plants are small modular industrial systems, which are designed and implemented to generate information and understand particular behaviours during test or trial periods. This is usually done before building the large full-scale plant, which entails large capital outlays as well as major risks associated with the process. The use of the pilot or bench plants enables one to make a calculated and informed decision on whether or not to move forward with the full-scale operation. It equips the client with freedom to run tests accurately as well as change and modify procedures on the smaller scale.

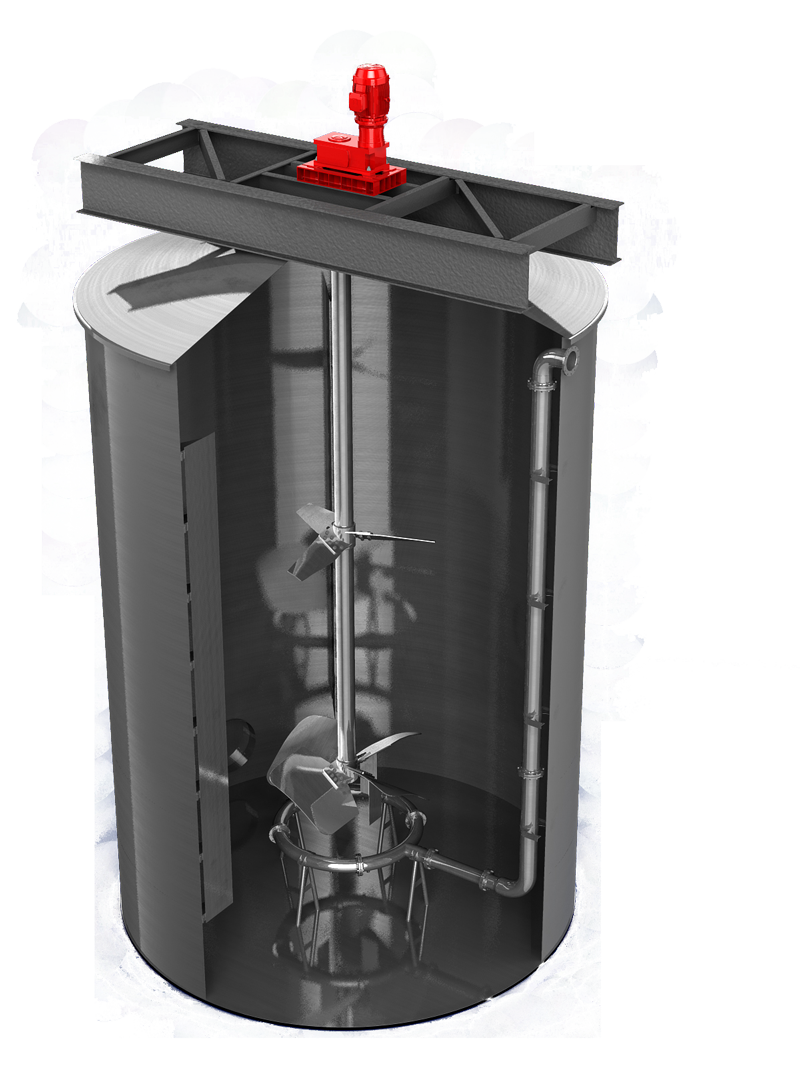

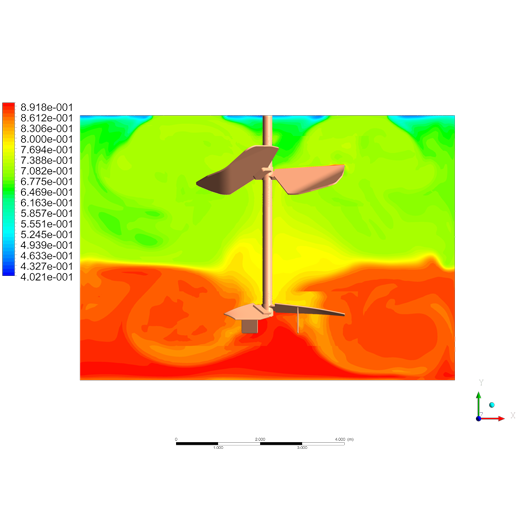

BAFFLES AND BAFFLE COILS

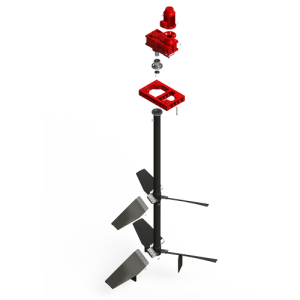

BAFFLES AND BAFFLE COILS Mounting bases and pedestals are critical in ensuring that the gearbox of the agitator is correctly aligned and mounted to the supporting beam structure. Our pedestals and bases are designed to significantly reduce the potential of twisting or flexing within the gearbox housing; which is often a common cause of some gearbox failures.

Mounting bases and pedestals are critical in ensuring that the gearbox of the agitator is correctly aligned and mounted to the supporting beam structure. Our pedestals and bases are designed to significantly reduce the potential of twisting or flexing within the gearbox housing; which is often a common cause of some gearbox failures. IMPELLER TYPE: F3

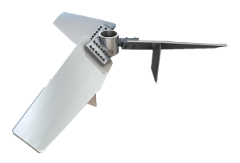

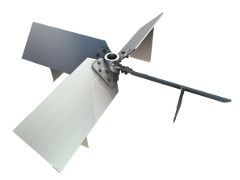

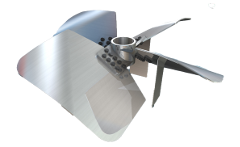

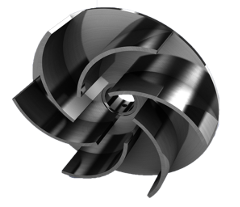

IMPELLER TYPE: F3 IMPELLER TYPE: FS4

IMPELLER TYPE: FS4 IMPELLER TYPE: P3

IMPELLER TYPE: P3 IMPELLER TYPE: P4

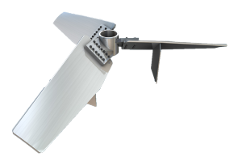

IMPELLER TYPE: P4 FOLDING IMPELLERS

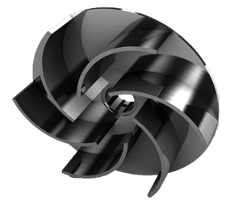

FOLDING IMPELLERS IMPELLER TYPE: R6

IMPELLER TYPE: R6 FCE3 CLEAN EDGE IMPELLER

FCE3 CLEAN EDGE IMPELLER

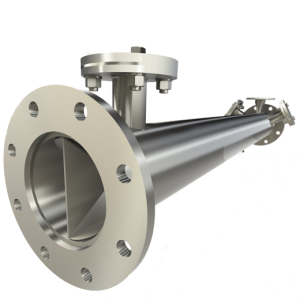

PRESSURE OXIDATION

PRESSURE OXIDATION GAS DISPERSION

GAS DISPERSION IRON REMOVAL

IRON REMOVAL CYANIDE DETOX

CYANIDE DETOX PEDESTAL MOUNTED MIXERS

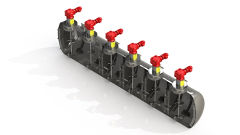

PEDESTAL MOUNTED MIXERS R6 PUMP IMPELLER

R6 PUMP IMPELLER

SIDE ENTRY AGITATORS

SIDE ENTRY AGITATORS TOP ENTRY MIXERS

TOP ENTRY MIXERS

SMALL TOP ENTRY AGITATORS

SMALL TOP ENTRY AGITATORS