Platinum and associated Platinum Group Metals (PGM) are recovered from Platinum and UG2 ore bodies. Base metals like copper, nickel and zinc are normally associated with the Platinum (PGM) ore bodies.

Process plant flow sheet includes crushing, milling, flotation, smelting and converting of concentrates, separation of Platinum, PGM and base metal products. The Platinum PGM product is forwarded to refineries for recovery of all metals.

Base metal recovery follows the high pressure autoclave oxidation route, iron removal and solvent extraction recovery.

Applications

Afromix equipment application in Platinum and base metal recovery plants.

Platinum and Base metal recovery

Crusher plants

Peristaltic pumps for the transfer of crusher slime thickener underflow to milling plant.

Peristaltic pumps Transfer of spillage to milling plant.

Milling Plants

Agitator for the surge tank before thickener with P3 or F3 impeller blades.

Thickener plant

Peristaltic pumps for the transfer of thickener underflow to the surge tank at the flotation plant.

Agitator for the surge tank with P3 impeller blades.

Iron Removal and Solvent Extraction

Agitators for base metal solution iron removal and solvent extraction (SX) plant for nickel recovery and iron removal.

Flotation plant to produce concentrates.

Flotation thickener

Peristaltic pumps for pumping thickener underflow to the smelter.

Agitator for the surge tank with P3 impeller blades.

Base metal Autoclaves

Low pressure and temperature treatment of base metal material.

Specialised agitators for autoclaves. P4 impeller blades are used in gas dispersion and aeration applications.

Thickeners

Peristaltic pumps for pumping thickener underflow to waste.

Mixing tank agitators before feeding to settlers.

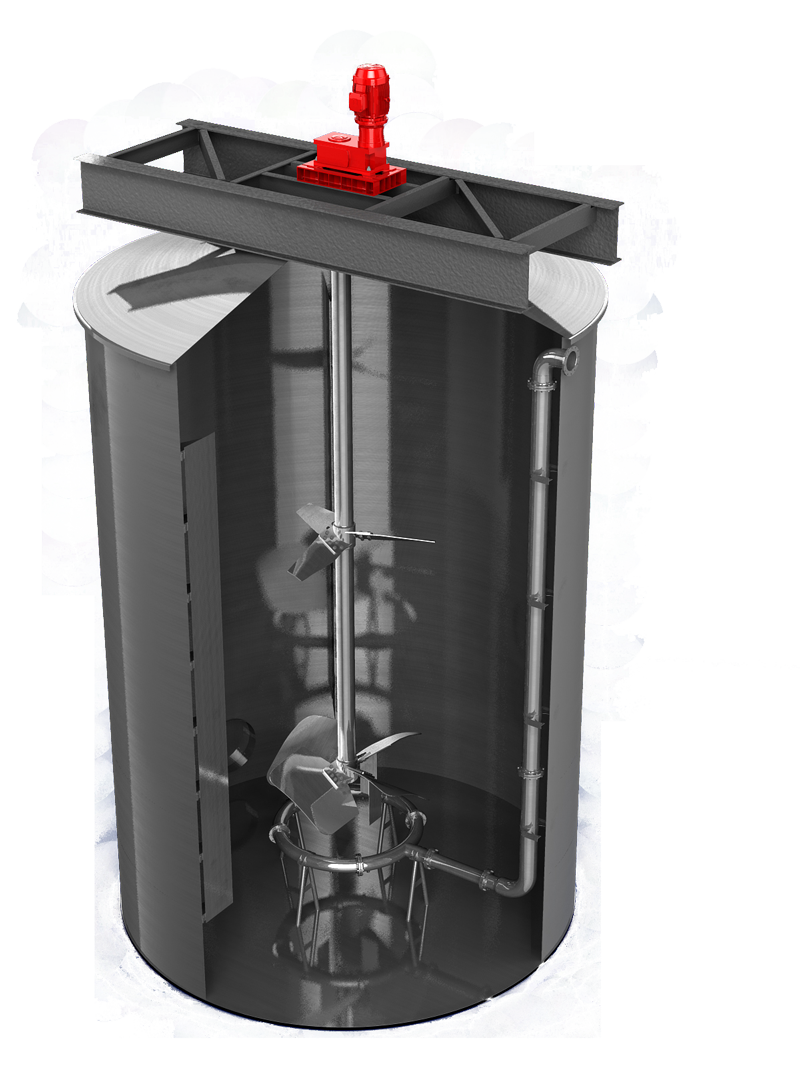

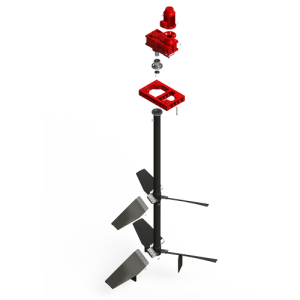

Dual Impeller System

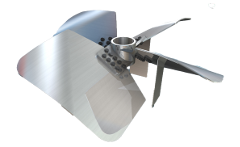

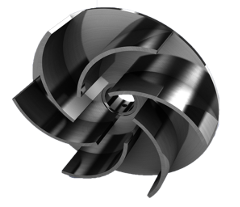

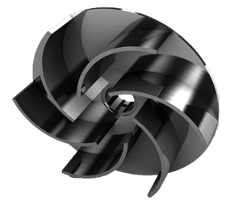

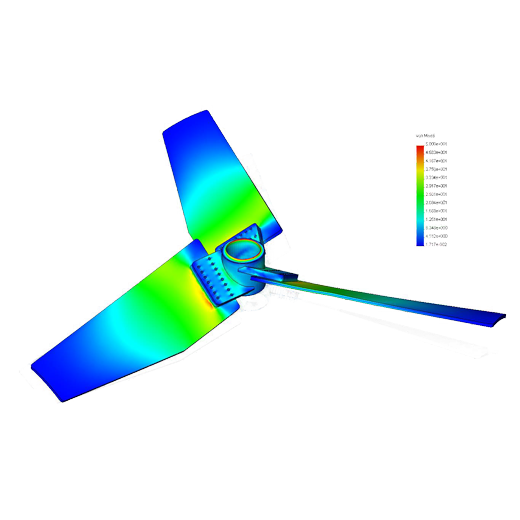

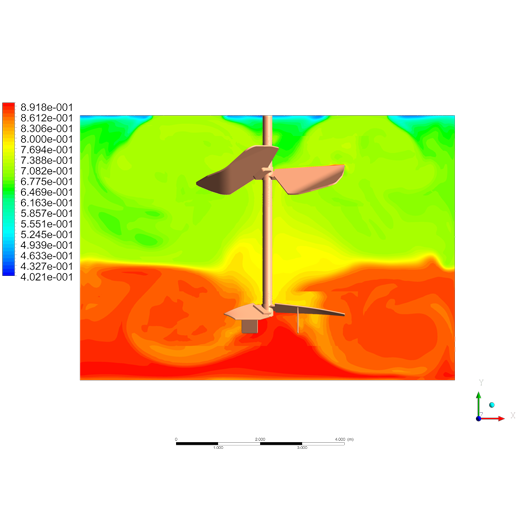

The lower impeller of the Afromix Dual Impeller System, known as the P4 impeller, is a downward pumping, four-bladed, high solidity hydrofoil impeller that has become the standard in reactors. Its function is to disperse high volumes of air while, at the same time, maintaining the solids in suspension, as well as promoting effective heat transfer. Such impellers, which typically have a solidity ratio of more than 90%, are characterised by their ability to operate at high gas volumes without flooding.

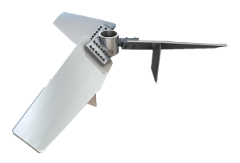

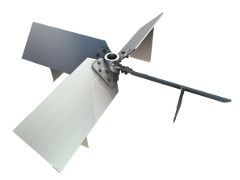

The upper impeller, known as the P3 impeller, is the innovative aspect of the Afromix Dual Impeller System. It is an upward-pumping triple-blade medium solidity impeller. Although originally designed for high-viscosity applications, the P3 impeller is also diverse enough to operate through three-phase or gas-liquid-solids applications.

With the help of the Afromix Dual Impeller System, the oxygen mass-transfer requirements of processes will be satisfied at a much lower power input and aeration rate, especially when compared to that of its predecessor, the single-impeller system. The system’s enhanced mass-transfer performance is achieved through surface air induction created by the top impeller, which is further enhanced by the gas hold-up from the specific mixing pattern created by the dual impeller configuration as a whole.

The air induced from the surface by the Dual Impeller System reduces the volume of external gas required, resulting in an overall power decrease. In addition to the improved performance, the Dual Impeller System also demonstrates a reduction in a bending moment, torque and thrust, ultimately extending the mechanical life of the agitator.

Advantages

The design is extremely effective with high mass-transfer applications, which can be achieved at lower power. In fact, one can achieve the same mass-transfer at 30-50% of the installed power. Superior oxygen utilisations.

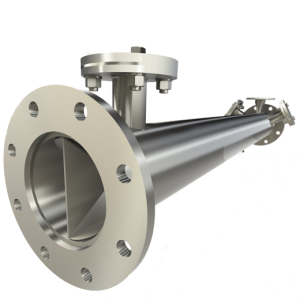

Gas can be entrained from the head volume or surface at very high rates, thus reducing, or completely eliminating, the need for sparges.

Dual impellers provide increased tank turnover rates and mixing abilities. This means that any reagents or additional acid is mixed in faster and more effectively.

Many autoclaves or reactors are currently fitted with Rushton or radial flow impellers, which provide very poor suspension and mixing capabilities. When it comes to optimal suspension, Afromix’s Dual Impeller System is superior, due to both impellers being axial flow.

Rushton or radial flow impellers, commonly used in reactors, only get one pass at the gas. This is a result of them not being able to hold down the gas or entraining gas from the head space.

Many systems that make use of air or enriched air achieve much higher oxygen utilisation. Test work based purely on air shows an oxygen utilisation increase of 40% increasing to over 60% in certain cases.

The dual system increases the gas hold down. Currently, a single impeller system can achieve a gas hold up of approximately 15%, in comparison to the dual system which can achieve 30% or higher.

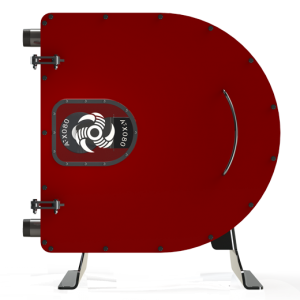

AFX Pumps

Pump abrasive fluids like tailings, metal slurries, and thickener underflow with ease.

Flow rates from 40m³/hr up to 150m³/hr.

Contains the fluid entirely within the hose.

Up to 50% savings on power consumption.

Hose ranges to fit most peristaltic pumps.

Give our team at AFX Holdings a call and we will find the best products for your platinum mining processes.

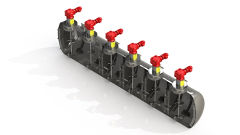

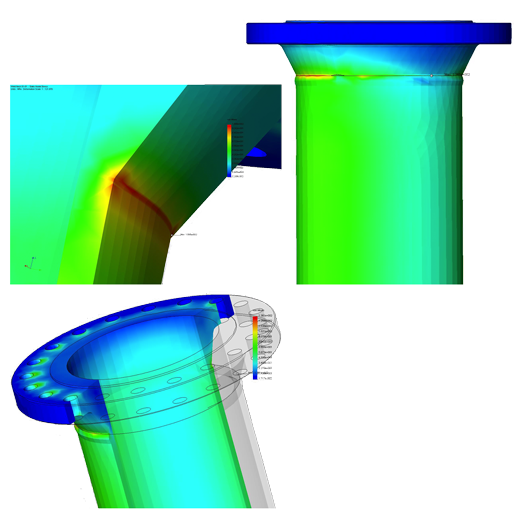

At the heart of every AFX peristaltic pump lies a heavy-duty peristaltic hose specially developed to work hand in hand with the pump roller technology installed in the AFX PUMP SERIES. We stock a comprehensive range of hose materials for each pump to be compatible with the unique chemical and abrasive characteristics of every application. A carefully designed and manufactured hose element is the single most vital component for the performance durability and efficiency of any peristaltic pump. To ensure a good pump you must have a good hose, and this is where AFX excels. Each hose we supply is built under stringent quality control measures, using high-quality, compounded rubbers, reinforced with four individual layers of braided nylon carefully set at optimum angles. Once cured, the outer diameter of each hose is precision machined to exacting tolerances ensuring a perfectly sized hose. An accurately sized hose ensures perfect compression, which eliminates internal slip (which reduces pump efficiency and allows for the abrasive slurries to prematurely destroy the hose).

At the heart of every AFX peristaltic pump lies a heavy-duty peristaltic hose specially developed to work hand in hand with the pump roller technology installed in the AFX PUMP SERIES. We stock a comprehensive range of hose materials for each pump to be compatible with the unique chemical and abrasive characteristics of every application. A carefully designed and manufactured hose element is the single most vital component for the performance durability and efficiency of any peristaltic pump. To ensure a good pump you must have a good hose, and this is where AFX excels. Each hose we supply is built under stringent quality control measures, using high-quality, compounded rubbers, reinforced with four individual layers of braided nylon carefully set at optimum angles. Once cured, the outer diameter of each hose is precision machined to exacting tolerances ensuring a perfectly sized hose. An accurately sized hose ensures perfect compression, which eliminates internal slip (which reduces pump efficiency and allows for the abrasive slurries to prematurely destroy the hose).

Peristaltic pumps are by nature inherently pulsing in operation. Excessive pressure spikes and pulsations within the pump system can be extremely damaging to the pump hose and the process system.

Peristaltic pumps are by nature inherently pulsing in operation. Excessive pressure spikes and pulsations within the pump system can be extremely damaging to the pump hose and the process system. The primary reason for hose failure is from cyclic fatigue (number of hose compressions). Pump hose failure is inevitable, but exactly when hose failure will occur is dependent upon many factors and may not always be at a convenient time when a technician is watching the pump.

The primary reason for hose failure is from cyclic fatigue (number of hose compressions). Pump hose failure is inevitable, but exactly when hose failure will occur is dependent upon many factors and may not always be at a convenient time when a technician is watching the pump. Our extensive range of peristaltic hose pumps includes one of the largest pumps of this type in the world. Our 150mm pump has a maximum flow rate of 147m³/hr and can deliver pressures up to 10 Bar. These units are ideal for thickener underflow applications.

Our extensive range of peristaltic hose pumps includes one of the largest pumps of this type in the world. Our 150mm pump has a maximum flow rate of 147m³/hr and can deliver pressures up to 10 Bar. These units are ideal for thickener underflow applications. OPERATING PRINCIPLE

OPERATING PRINCIPLE PUMP SELECTION

PUMP SELECTION spreading from mining processes to chemical and agricultural testing laboratories as well as personal care and pharmaceutical laboratories, the need for this equipment is on the rise. Pilot plants and bench plants are small modular industrial systems, which are designed and implemented to generate information and understand particular behaviours during test or trial periods. This is usually done before building the large full-scale plant, which entails large capital outlays as well as major risks associated with the process. The use of the pilot or bench plants enables one to make a calculated and informed decision on whether or not to move forward with the full-scale operation. It equips the client with freedom to run tests accurately as well as change and modify procedures on the smaller scale.

spreading from mining processes to chemical and agricultural testing laboratories as well as personal care and pharmaceutical laboratories, the need for this equipment is on the rise. Pilot plants and bench plants are small modular industrial systems, which are designed and implemented to generate information and understand particular behaviours during test or trial periods. This is usually done before building the large full-scale plant, which entails large capital outlays as well as major risks associated with the process. The use of the pilot or bench plants enables one to make a calculated and informed decision on whether or not to move forward with the full-scale operation. It equips the client with freedom to run tests accurately as well as change and modify procedures on the smaller scale.

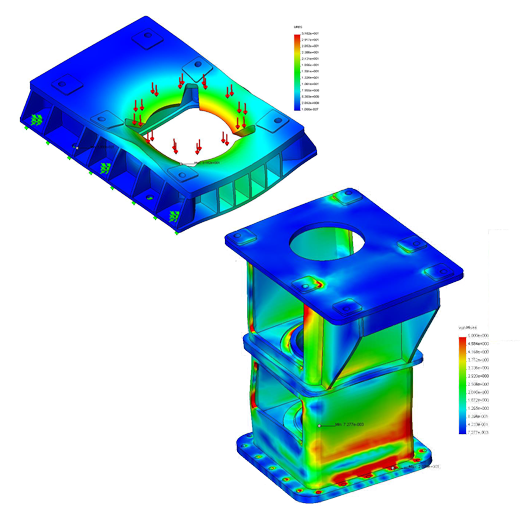

BAFFLES AND BAFFLE COILS

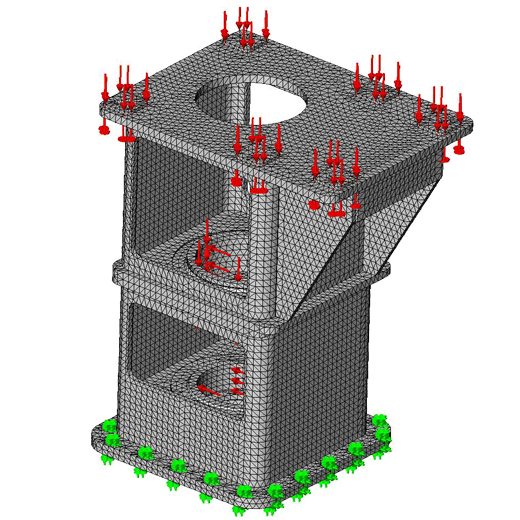

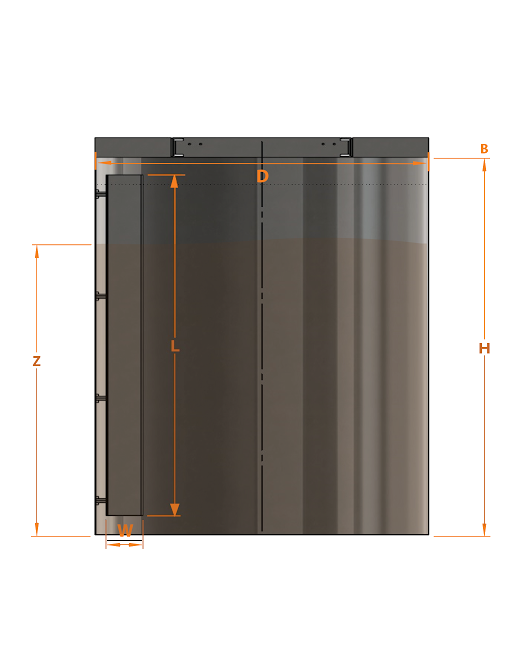

BAFFLES AND BAFFLE COILS Mounting bases and pedestals are critical in ensuring that the gearbox of the agitator is correctly aligned and mounted to the supporting beam structure. Our pedestals and bases are designed to significantly reduce the potential of twisting or flexing within the gearbox housing; which is often a common cause of some gearbox failures.

Mounting bases and pedestals are critical in ensuring that the gearbox of the agitator is correctly aligned and mounted to the supporting beam structure. Our pedestals and bases are designed to significantly reduce the potential of twisting or flexing within the gearbox housing; which is often a common cause of some gearbox failures. IMPELLER TYPE: F3

IMPELLER TYPE: F3 IMPELLER TYPE: FS4

IMPELLER TYPE: FS4 IMPELLER TYPE: P3

IMPELLER TYPE: P3 IMPELLER TYPE: P4

IMPELLER TYPE: P4 FOLDING IMPELLERS

FOLDING IMPELLERS IMPELLER TYPE: R6

IMPELLER TYPE: R6 FCE3 CLEAN EDGE IMPELLER

FCE3 CLEAN EDGE IMPELLER

PRESSURE OXIDATION

PRESSURE OXIDATION GAS DISPERSION

GAS DISPERSION IRON REMOVAL

IRON REMOVAL CYANIDE DETOX

CYANIDE DETOX PEDESTAL MOUNTED MIXERS

PEDESTAL MOUNTED MIXERS R6 PUMP IMPELLER

R6 PUMP IMPELLER

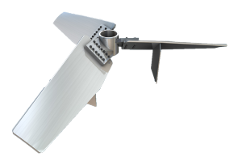

SIDE ENTRY AGITATORS

SIDE ENTRY AGITATORS TOP ENTRY MIXERS

TOP ENTRY MIXERS

SMALL TOP ENTRY AGITATORS

SMALL TOP ENTRY AGITATORS

Recent Comments