LATEST NEWS

WOMEN AT WORK

WOMEN AT WORKWhy Women Matter in the Workforce – and What It Means for AFXIn honour of Women’s Month | 7 August 2025 | By Anje Barkhuizen There’s no denying that businesses do better when they reflect the real world. And the real world is made up of women with...

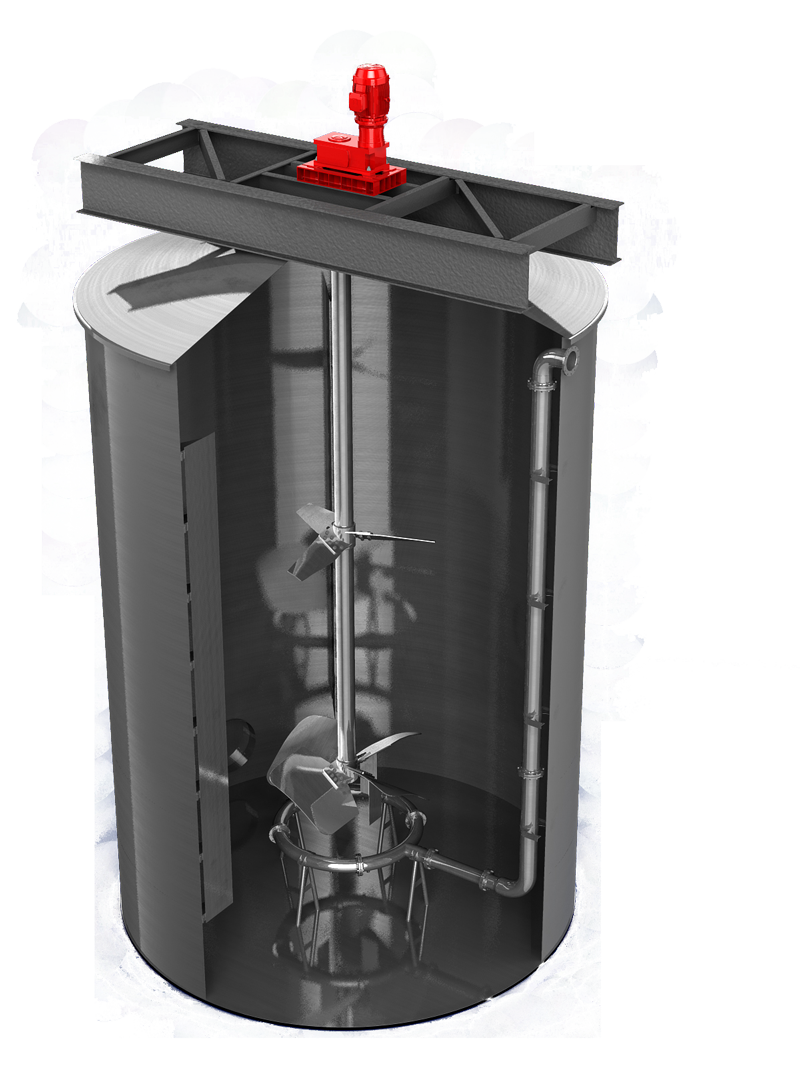

AFROMIX – Keeping Fluid in Motion

AFX Mixing and Pumping Technologies Ltd

We are extremely proud of the amazing work our UK Office is doing. COVID-19 is a scary reality across the world and South Africa is yet to reach its peak. AFROMIX, our various branches and representation across the globe can assist with these agitators.Contact us on...

AFX Holdings – Covid-19

Dear valued client and supplier, Currently, our Headquarters and branch offices are working regularly without interruptions caused by material or workforce unavailability. AFROMIX’s product range of AMX Agitators and AFX Peristaltic Pumps are 100% locally manufactured...

Pipes, Pumps & Valves Africa

Endorsed By SAPMA, SAPSDA, SAVAMA & VAMCOSA South African pump manufacturer Afromix has designed and developed a robust pumping solution delivering exceptional performance the world over. Pipes Pumps & Valves Africa sat down with managing director, Eugene Els,...

Kenridge Primary

Afromix sponsored the Kenridge Primary (Cape Town) U/13’s 1st rugby team with training shirts.

Machining Department Team

As AFROMIX has recently acquired a couple of new machines, we added some amazing people to the Machining Department Team! From left: Zimkhitha Nxadi - Machinist Xoliseka Gana - Machinist Louis Theron - CNC Programmer Reon Schoeman - Process Technician Ryno Gerber -...

Platinum Mine Applications

Platinum and associated Platinum Group Metals (PGM) are recovered from Platinum and UG2 ore bodies. Base metals like copper, nickel and zinc are normally associated with the Platinum (PGM) ore bodies. Process plant flow sheet includes crushing, milling, flotation,...

Copper Mine Applications

At AFX Holdings we offer top of the range products for copper mining applications. In the below blog piece you will find out in which copper mine applications our products are used. Applications where our products are used in the copper mining process...

ELECTRAMINING 2018

After months of preparation for one of the biggest mining shows in the world, Electra mining 2018 finally arrived! We had a great week exhibiting some of our most sought after equipment and interacting with old and new clients. Some technological...

Gold Mine Applications.

At AFX Holdings we offer top of the range products for gold mining applications. In this blog piece you will find out in which gold mine applications our products are used. Applications where our products are used in the gold mining process include: Crusher plants...

We have a new Agitator on the market.

AMX agitator for the food and pharmaceutical industry. This specific unit will be used to mix vitamin products. The Agitator is used in application where the atmospheric pressure is the same inside and outside the tank. Some examples of food and pharmaceutical...

Our work in photos

ELECTRA MINING 2016

AFROMIX took part in Electra Mining 2016. Electra Mining is the biggest mining exhibition in Southern Africa. AFROMIX exhibited their AFX150 peristaltic pump and latest agitator technology at the exhibition.

AFX PUMPS AND AMX AGITATORS TRAINING

On the 9th and the 10th of November 2016 AFROMIX hosted their first in-house training and it was presented by Toby Frostwich and Eugene Els. The training was based on the company’s product...

CYANIDE DETOX IN EAST AFRICA

AFROMIX recently supplied four large Cyanide Detox Agitators to a mine in Eastern Africa. These units are able to provide high mass transfer but still able to keep the solid suspended uniformly. Sufficient air is required with SO2 gas to destroy the cyanide...

SX Mixers in the DRC

AFROMIX recently supplied four large Cyanide Detox Agitators to a mine in Eastern Africa. These units are able to provide high mass transfer but still able to keep the solid suspended uniformly. Sufficient air is required with SO2 gas to destroy the cyanide complex....

URANIUM PLANT IN NAMIBIA

A major, new uranium plant in Namibia was experiencing constant mechanical failures on their recently installed agitators. Problems included shaft breakages, gearbox failure, and other associated problems. After a visit to the site AFROMIX submitted a report, together...

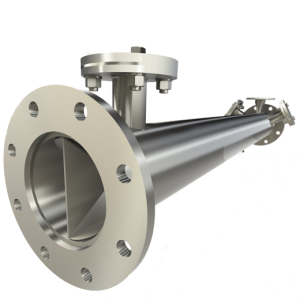

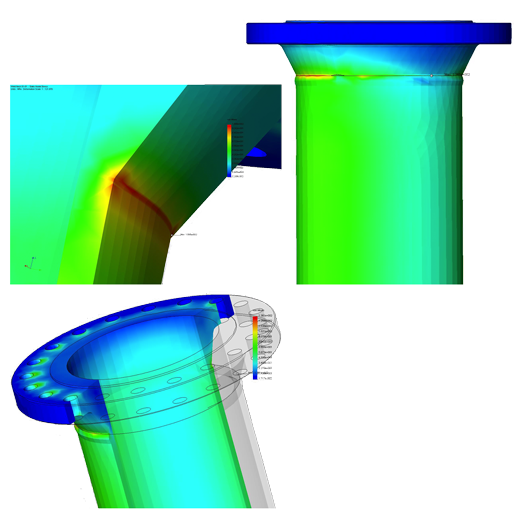

At the heart of every AFX peristaltic pump lies a heavy-duty peristaltic hose specially developed to work hand in hand with the pump roller technology installed in the AFX PUMP SERIES. We stock a comprehensive range of hose materials for each pump to be compatible with the unique chemical and abrasive characteristics of every application. A carefully designed and manufactured hose element is the single most vital component for the performance durability and efficiency of any peristaltic pump. To ensure a good pump you must have a good hose, and this is where AFX excels. Each hose we supply is built under stringent quality control measures, using high-quality, compounded rubbers, reinforced with four individual layers of braided nylon carefully set at optimum angles. Once cured, the outer diameter of each hose is precision machined to exacting tolerances ensuring a perfectly sized hose. An accurately sized hose ensures perfect compression, which eliminates internal slip (which reduces pump efficiency and allows for the abrasive slurries to prematurely destroy the hose).

At the heart of every AFX peristaltic pump lies a heavy-duty peristaltic hose specially developed to work hand in hand with the pump roller technology installed in the AFX PUMP SERIES. We stock a comprehensive range of hose materials for each pump to be compatible with the unique chemical and abrasive characteristics of every application. A carefully designed and manufactured hose element is the single most vital component for the performance durability and efficiency of any peristaltic pump. To ensure a good pump you must have a good hose, and this is where AFX excels. Each hose we supply is built under stringent quality control measures, using high-quality, compounded rubbers, reinforced with four individual layers of braided nylon carefully set at optimum angles. Once cured, the outer diameter of each hose is precision machined to exacting tolerances ensuring a perfectly sized hose. An accurately sized hose ensures perfect compression, which eliminates internal slip (which reduces pump efficiency and allows for the abrasive slurries to prematurely destroy the hose).

Peristaltic pumps are by nature inherently pulsing in operation. Excessive pressure spikes and pulsations within the pump system can be extremely damaging to the pump hose and the process system.

Peristaltic pumps are by nature inherently pulsing in operation. Excessive pressure spikes and pulsations within the pump system can be extremely damaging to the pump hose and the process system. The primary reason for hose failure is from cyclic fatigue (number of hose compressions). Pump hose failure is inevitable, but exactly when hose failure will occur is dependent upon many factors and may not always be at a convenient time when a technician is watching the pump.

The primary reason for hose failure is from cyclic fatigue (number of hose compressions). Pump hose failure is inevitable, but exactly when hose failure will occur is dependent upon many factors and may not always be at a convenient time when a technician is watching the pump. Our extensive range of peristaltic hose pumps includes one of the largest pumps of this type in the world. Our 150mm pump has a maximum flow rate of 147m³/hr and can deliver pressures up to 10 Bar. These units are ideal for thickener underflow applications.

Our extensive range of peristaltic hose pumps includes one of the largest pumps of this type in the world. Our 150mm pump has a maximum flow rate of 147m³/hr and can deliver pressures up to 10 Bar. These units are ideal for thickener underflow applications. OPERATING PRINCIPLE

OPERATING PRINCIPLE PUMP SELECTION

PUMP SELECTION spreading from mining processes to chemical and agricultural testing laboratories as well as personal care and pharmaceutical laboratories, the need for this equipment is on the rise. Pilot plants and bench plants are small modular industrial systems, which are designed and implemented to generate information and understand particular behaviours during test or trial periods. This is usually done before building the large full-scale plant, which entails large capital outlays as well as major risks associated with the process. The use of the pilot or bench plants enables one to make a calculated and informed decision on whether or not to move forward with the full-scale operation. It equips the client with freedom to run tests accurately as well as change and modify procedures on the smaller scale.

spreading from mining processes to chemical and agricultural testing laboratories as well as personal care and pharmaceutical laboratories, the need for this equipment is on the rise. Pilot plants and bench plants are small modular industrial systems, which are designed and implemented to generate information and understand particular behaviours during test or trial periods. This is usually done before building the large full-scale plant, which entails large capital outlays as well as major risks associated with the process. The use of the pilot or bench plants enables one to make a calculated and informed decision on whether or not to move forward with the full-scale operation. It equips the client with freedom to run tests accurately as well as change and modify procedures on the smaller scale.

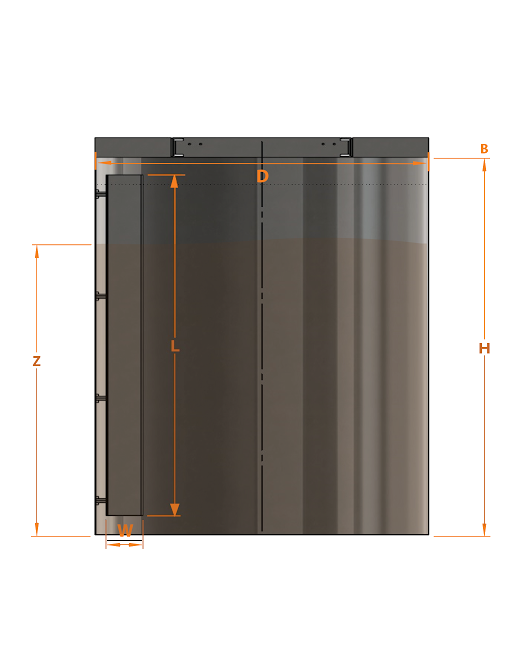

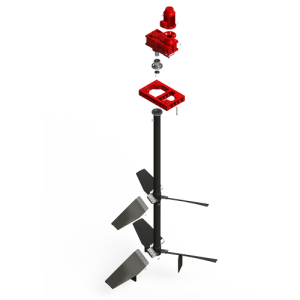

BAFFLES AND BAFFLE COILS

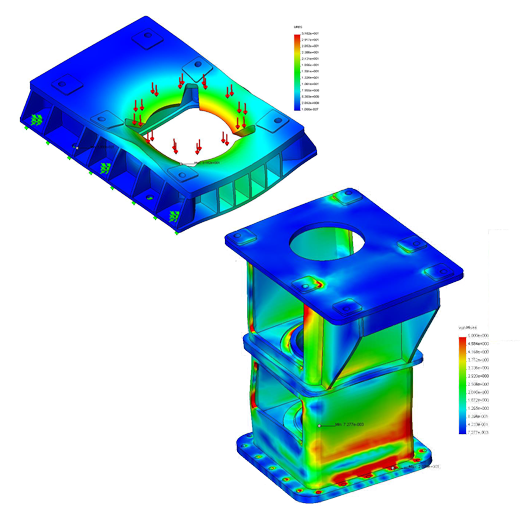

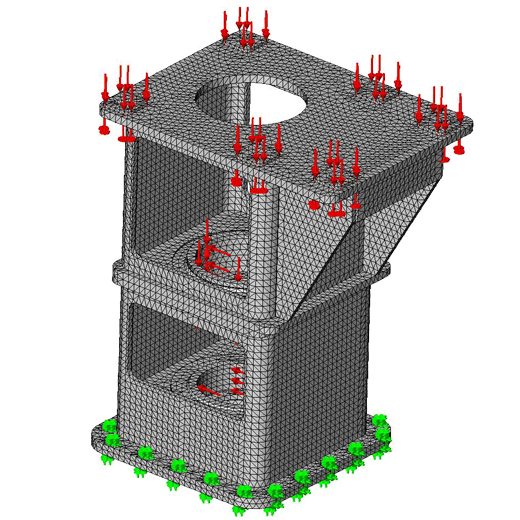

BAFFLES AND BAFFLE COILS Mounting bases and pedestals are critical in ensuring that the gearbox of the agitator is correctly aligned and mounted to the supporting beam structure. Our pedestals and bases are designed to significantly reduce the potential of twisting or flexing within the gearbox housing; which is often a common cause of some gearbox failures.

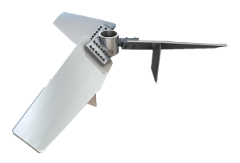

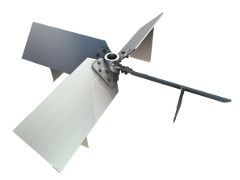

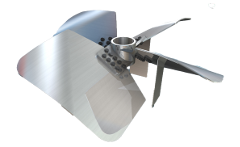

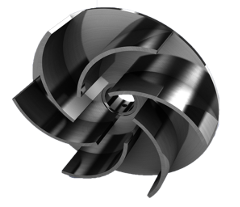

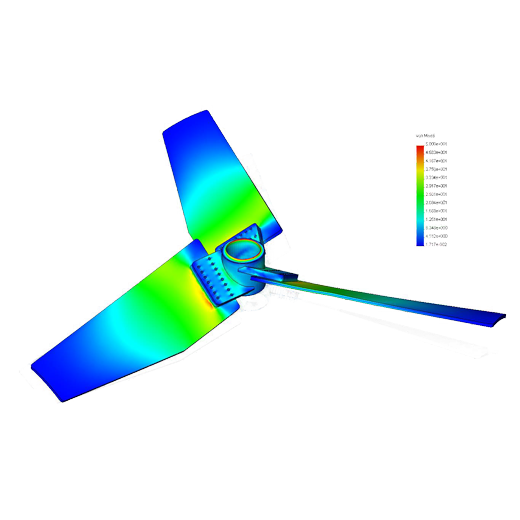

Mounting bases and pedestals are critical in ensuring that the gearbox of the agitator is correctly aligned and mounted to the supporting beam structure. Our pedestals and bases are designed to significantly reduce the potential of twisting or flexing within the gearbox housing; which is often a common cause of some gearbox failures. IMPELLER TYPE: F3

IMPELLER TYPE: F3 IMPELLER TYPE: FS4

IMPELLER TYPE: FS4 IMPELLER TYPE: P3

IMPELLER TYPE: P3 IMPELLER TYPE: P4

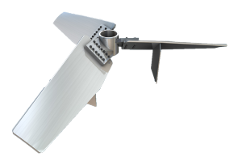

IMPELLER TYPE: P4 FOLDING IMPELLERS

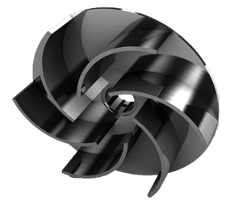

FOLDING IMPELLERS IMPELLER TYPE: R6

IMPELLER TYPE: R6 FCE3 CLEAN EDGE IMPELLER

FCE3 CLEAN EDGE IMPELLER

PRESSURE OXIDATION

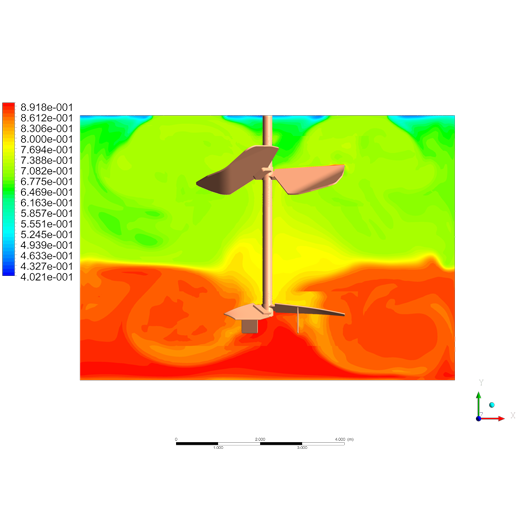

PRESSURE OXIDATION GAS DISPERSION

GAS DISPERSION IRON REMOVAL

IRON REMOVAL CYANIDE DETOX

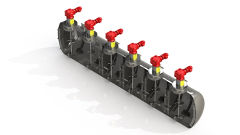

CYANIDE DETOX PEDESTAL MOUNTED MIXERS

PEDESTAL MOUNTED MIXERS R6 PUMP IMPELLER

R6 PUMP IMPELLER

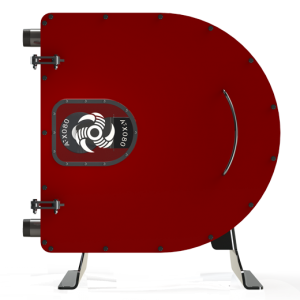

SIDE ENTRY AGITATORS

SIDE ENTRY AGITATORS TOP ENTRY MIXERS

TOP ENTRY MIXERS

SMALL TOP ENTRY AGITATORS

SMALL TOP ENTRY AGITATORS